Article Index

THE SERVICE BOX

While the silicon sensors and the hybrids are located in the service boxes, the digitizing and control electronics is located in the service boxes, out of the detector acceptance. This reduces the amount of dead material and hence multiple scattering and generation of secondary particles. In addition, the location of the Service Boxes, features lower radiation levels and easier access for cooling and maintenance.

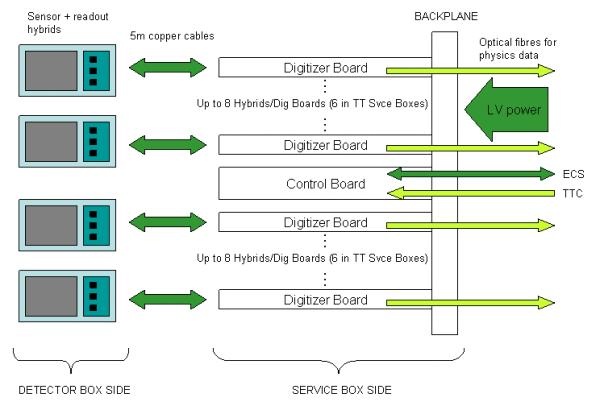

Each Service Box holds up to 16 Digitizer Boards, which handle the signals coming from and going to the readout hybrids. As this includes not only the physics data, but also power supply, timing and slow control signals, this allows for a single cable connection between a hybrid and its associated Digitizer Board. For each Service Box, a Control card provides the interface to the experiment-wide Timing and Fast Control system (TFC) and the Experiment Control System (ECS). The distribution of these signals among the Digitizer Board within a Service Box is done with a customdesigned backplane. The backplane also carries the radiationtolerant linear voltage regulators to supply the readout hybrids and the Service Box itself. An overview scheme of a Service Box is shown in the figure below.

THE TELL1 ELECTRONIS

In the counting house is located the "L1 electronics" whose purpose is the handling L0 accepted databefore transmission to the DAQ. The data are transferred by optical lines from the service boxes to the counting houses. There the TELL1 boards perform deserialization, some data processing, followed by transmission of the compressed data to the L1 and HLT trigger CPU farm.

LOW VOLTAGE AND HIGH VOLTAGE

Besides the acquisiton, digitization, processing and transmission electronics of the L0 and L1 electronics, some electronic infrastructure such as the Low voltage and High voltage voltage power supplies is essential to power the systems.

Although it could seem a trivial task, the proper selection, distribution and installation of the power systems is a crucial for the proper working of the complete detector. This is a part closely related to the grounding and shielding management of the Silicon Tradker detector. The careful design of grounding, shielding and power distribution strategy is essential in big elementary particle detectors.